| Manufacturing Capabilities |

|

|

|

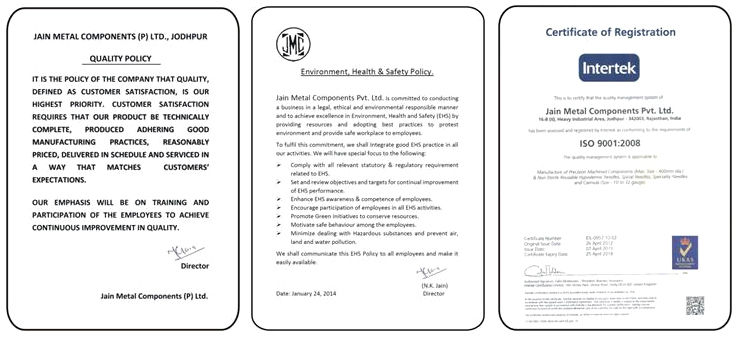

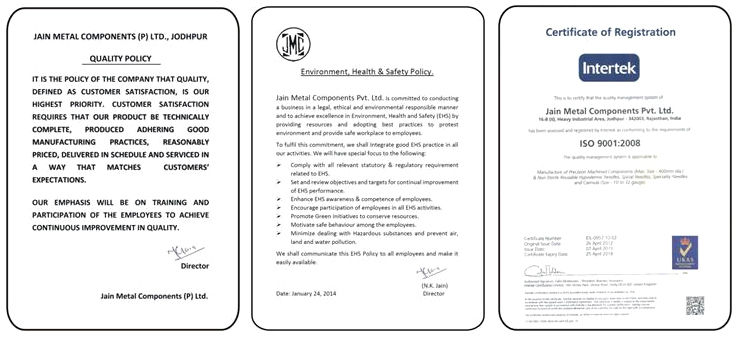

JAIN METAL COMPONENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

| Manufacturing Capabilities |

|

|

|

JAIN METAL COMPONENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |