|

Jain Metal Components Pvt. Ltd.

|

|

|

Iscon Surgicals Ltd. |

|

Products Portfolio

We are famous for manufacturing, supplying and exporting below cited products :

- CNC Lathe Machines

- VMC Machines

- Programmable Logic Controllers (PLC)

- CNC Automatic Grinders

- Molding Machines

- Supporting Machines

- Tool Room Equipment

- Needles

- Hydraulic Pumps

- Motors

- Hydraulic Fittings

- Pneumatic Fittings

- Tap Changers

- Switchgears

- Electrical Products

- LPG Gas Cylinders

- Regulator Valves

- Industrial Valves, Industrial Control Valves

- Relief Valves

- Control Valves

- Assemblies for Electric Circuit Breakers

- Parts for Diesel Locomotives Parts

- Tractor Parts

- Cable Glands

- Sprinkler Parts

- Components for MIG & TIG Welding Torches

- Flashback Arrestors

- Gas Mixers

- Accessories for Induction Furnaces

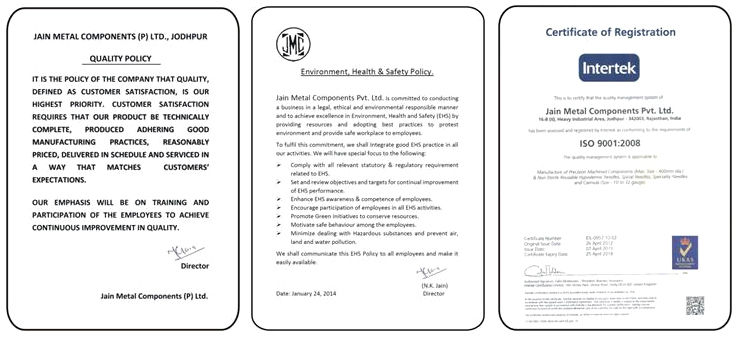

Quality Assurance

- Conventional measuring instruments & gauge for dimensions

- Electrical conductivity tests

- Hardness tester (Vickers, Rockwell)

- Leakage testing products

- Platting thickness tester

- Profile projector for irregular profiles & angles

Our Facilities

|

Specialized Tasks |

Machines & Equipment |

|

Machining & Fabrication |

|

|

Surface Treatment |

|

|

Brazing |

Silver Brazing Equipment |

|

Moulding |

Plastics Engineering, Design & Tool Room |

Awards

Our

high professionalism, quality products and market leading rates have

earned reputation for us in the market. Due to our superior quality

control, rising growth rate and export focus, we have been periodically

awarded by various Government & Semi-government agencies such as

State Excellence Award by State Government of Rajasthan, National

Quality Award by Ministry of Industries (Government of India) and Udyog

Ratna Award by Delhi Surgical & Traders Association.

|

|

JAIN METAL COMPONENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |